Fuel Injectors

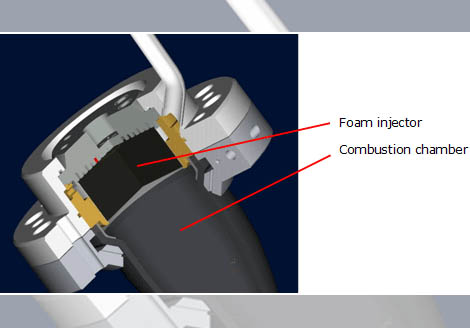

High temperature, open-cell foams fabricated by Ultramet have excellent strength, oxidation resistance, and thermal shock resistance. Because these foams yield high performance mixing with low pressure drop, they can be used within the combustion zones of rocket engines.

Advantages

- Uniformly porous

- Available in refractory metal and ceramic materials with tailorable pore size and mechanical/thermal properties

- Fracture strength of >800 MPa

- High creep and thermal shock resistance

- 4352°F (2400°C) sustained use temperature

- Predictable and straightforward design

- Ease of manufacture and assembly

- Reduced combustion instability

0.4% of the foam’s frontal area, is evenly and quickly redistributed across entire cross-section of foam sample. Effective homogenization of a flowing gas stream by Ultramet foam. Incoming gas jet, which has a cross-section of 0.4% of the foam’s frontal area, is evenly and quickly redistributed across entire cross-section of foam sample.

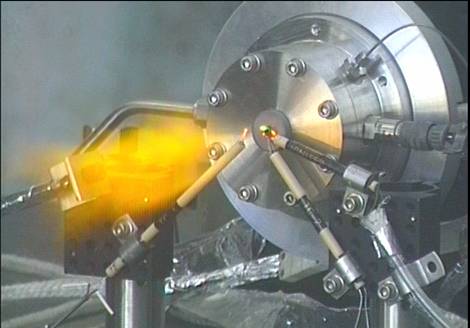

Gaseous hydrogen/air hot-fire test of Ultramet ceramic open-cell foam injector at the Air Force Research Laboratory (Edwards AFB)

Gaseous hydrogen/air hot-fire test of Ultramet ceramic open-cell foam injector at the Air Force Research Laboratory (Edwards AFB)

Ultramet refractory materials economically and effectively address the fabrication, pressure drop, mixing, and thermal management challenges encountered in current fabrication processes for liquid rocket injectors.